رد کردن این واقعیت که مهندسی عمران یکی از قدیمیترین و همزمان با این، شغل میانگین مشخصترین است در جامعه انسانی وجود ندارد. این برای ساختن ساختمانهای بسیاری مثل خانهها، مدارس، بیمارستانها و موارد مشابه استفاده میشود. یکی از اینها بتن است که به عنوان عمود مرکزی تقریباً هر پروژه ساخت و ساز عمل میکند و معمولاً از طریق مولفههایی مانند آب و مخلوطهای از شن و سیمان فرموله میشود. نوع جدیدی از بتن، بتن فیبری است که متخصصان در طول توسعه شهری از آن استفاده میکنند.

تغییر دادن ترکیب چیزی است که بتن فیبری را دستهبندی میکند: به عنوان مثال، افزودن فیبرهای کوچک (معمولاً شیشهای، فولادی یا پلاستیکی). این نوع جدید بتن از نظر مقاومت کششی قویتر و محکمتر از انواع سنتی است. همچنین دارای مزایای زیاد دیگری است که این گزینه را در میان سازندگان محبوب کرده است.

با اختراع جدید، با افزودن مواد فیبری به بتن فیبری، مقاومت کششی بتن به طور قابل توجهی افزایش مییابد. اینجا است که این فیبرها، وقتی اضافه شده و با بتن مخلوط میشوند، نقش مهمی در تقویت آن ایفا میکنند. به عبارت دیگر، بتن دیگر تحت فشار بالا به راحتی شکسته یا ترک خورده نمیشود - ویژگی اهمیتداری در ساخت و ساز از لحاظ مقاومت.

علاوه بر این، فیبرهای موجود در بتن فیبری نیز به راحتی قابل پردازشتر هستند. با داشتن بتن ساختاری محکمتر، سازههای نازکتر و سبکتر قابل ساخت هستند. به این ترتیب، کاهش مواد در ساخت و ساز زمان و منابع مورد نیاز برای هر کار ساختمانی را به طور قابل توجهی کاهش میدهد و همچنین منجر به صرفهجوییهای زیاد میشود.

صنعت بتن با تقویت فیبری قدرتمندتر و طولانیمدتتر میشود

این فیبر میتوانست قبلاً یک انقلاب برای صنعت فولاد بتن باشد، که در گذشته ساختمانها را با شن، آب و سیمان در تولید آنها ساخته و ساختمانها را ناقص تجهیز میگذاشت. اما تقویت با فیبر به طور کامل این موضوع را تغییر داد و با افزایش قابل مشاهده مقاومت کششی و استحکام بتن، آن را بهبود بخشید.

در نهایت، تقویت با فیبر به طراحان گذرنامهای آزاد داد تا ساختمانهایی که قبلاً فکر میشد سخت و سنگین هستند را ساخته باشند. بتن فیبری میتواند به سادگی برای ساخت گلولهها یا دیوارهای خمیده استفاده شود، زیرا قبلاً با فیبرهایی تقویت شده است و بنابراین قابلیت خمش بیشتری دارد.

یک بتن فیبری ساخته شده از مواد بازیافتی جایگزین پایداری برای آینده است. این نوع بتن معمولاً شامل فیبرهایی است که از پلاستیک یا فولاد بازیافتی ساخته شدهاند و بنابراین از فرستادن زباله به محل مدفن جلوگیری میکند.

این مقاومت کششی به همراه طول عمر بتن فیبری، به این معناست که نیاز به جایگزینی آن به دلیل خرج و سپری شدن، نسبت به بتنهای سنتی کمتر خواهد بود. این محکامی زمان و پول سازندگان را که نباید مخزنها را به صورت مکرر جایگزین کنند، صرفهجویی میکند، اما در بلندمدت منابع ارزشمند نیز.

فیبرهای قابل استفاده در پروژههای سطوح بتنی، ضخامت و همچنین مقاومت کششی را افزایش میدهند. یک پروژه مسکونی، هابیتات ۲۰۰۰ در آفریقای جنوبی، مسکنهای مقاومتر و طولانیتر با دسترسی آسانتر برای مردم با استفاده از بتن فیبری ساخت. دو نوع از اینها خانههای پیش ساخته از بتن تقویت شده هستند که قادر به تحمل هر شرایط آب و هوایی هستند و همچنان عمل میکنند.

در مورد برجهای سبز نانجینگ، که در دو ساختمان شهری بزرگ در چین کاشته شدهاند که از بتن فیبری / ByCONCEPT ساخته شدهاست. به همین دلیل، انعطافپذیری آن برای انجام کار ساختاری با اشکال و طراحیهای اختصاصی، بتن تقویت شده با فیبر را مواد خاصی میکند.

بتن فیبری روش جدیدی در ساخت و ساز است که با استفاده از فیبرها، مقاومت و انعطاف پذیری بیشتری نسبت به بتن معمولی ارائه میدهد. چون فیبرها در بتن مخلوط میشوند، این ماده به شکل فوق العاده مقاومی تبدیل میشود و قادر است فشارهای زیاد را بدون آسیب دائمی جذب کند. به طور خلاصه، نگهبانان محیط زیست به طور سریع به لولههای بتن فیبری نگاهی دقیقتری میاندازند و مشتاقانه به اینکه این محصول زمان ساخت را کاهش میدهد و همچنین دوستانه با محیط زیست است، علاقه مند میشوند.

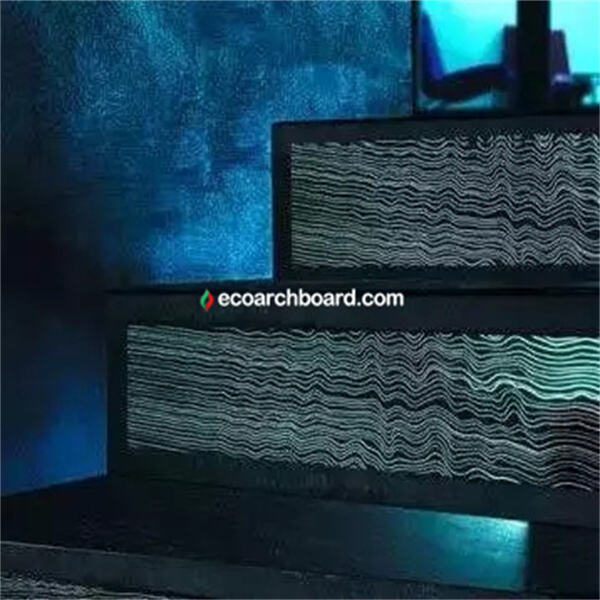

شانگهای اکو-آرچ با بهرهگیری از بیش از ۱۱ سال تجربه در زمینه نوآوریهای تحقیق و توسعه (R&D)، پیشروی بازار مواد ساختمانی پایدار را بر عهده دارد. این تجربه غنی در طیف گستردهای از محصولات خود نمایان است، از جمله: تختههای دیواری طلاکاریشده هنری، تختههای سیمانی سنگآهک طلاکاریشده، کاشیهای بتنی انعطافپذیر الیافی، و سنگهای نرم سهبعدی تراورتین. تیم بسیار متخصص طراحان و مهندسان این شرکت بهطور مداوم مرزهای علم مواد را گسترش داده و جدیدترین روشها و رویکردهای پایدار را در محصولات خود ادغام میکند. تعهد این شرکت به نوآوری بدین معناست که محصولات آن نهتنها مطابق با استانداردهای صنعتی هستند، بلکه از آنها فراتر رفته و استحکام استثنایی، جذابیت زیباییشناختی و مزایای زیستمحیطی قابلتوجهی ارائه میدهند. با انتخاب اکو-آرچ بهعنوان شریک، شما سازمانی را بهدست میآورید که متعهد به ارائه راهحلهای پیشرفتهای برای برآوردن نیازهای فعلی در حوزه ساختوساز است و این تعهد با سابقهای مستحکم از بیش از ۱۰۰٬۰۰۰ مورد همکاری موفق در سراسر جهان پشتیبانی میشود.

در شانگهای اکو-آرچ، کنترل کیفیت بخشی جداییناپذیر از سیاست تولید است. ما اهمیت قابلیت اطمینان و دوام در مواد ساختمانی را درک میکنیم. به همین دلیل، پروتکلهای دقیق تضمین کیفیت را در هر مرحلهای از فرآیند تولید اجرا میکنیم. امکانات مدرن ما برای آزمون محصولاتی مانند تختههای سیمانی فیبری (Fiber Cement Boards) و بتن نیمهشفاف (Translucent Concrete) از نظر ایمنی و عملکرد تجهیز شدهاند. هر محصول تحت بازرسی جامعی قرار میگیرد تا ابعاد، رنگ و یکپارچگی ساختاری آن تعیین شود. این رویکرد مبتنی بر بتن فیبری تضمین میکند که هر محصولی که از واحد تولیدی ما خارج میشود، در شرایطی کامل و بینقص ارسال میگردد. تعهد ما به کیفیت، اطمینانی را به مشتریان ارائه میدهد که در محصولاتی سرمایهگذاری میکنند که ترکیبی از هنرمندی برتر و مقاومت استثنایی هستند؛ و این امر باعث شده است که اکو-آرچ به عنوان یک نام معتبر در این صنعت شناخته شود.

شانگهای اکو-آرچ، رهبر در ارائه راهحلهای سفارشی برای برآوردن نیازهای هر مشتری است. این امر نشاندهنده تعهد ما به ارائه تجربهای شخصیسازیشده برای مشتریان ماست. مجموعه محصولات ما شامل بیش از ۳۰۰۰ محصول با کیفیت بالا است، از جمله پنلهای دیواری طلاکاریشده هنری، کاشیهای سرامیکی انعطافپذیر و تختههای بتنی، که همگی قابل سفارشیسازی برای تطبیق با هر نیاز پروژهای هستند. ما با درک دقیق نیازهای منحصربهفرد مشتریان خود افتخار میکنیم و نمونههای رایگان بتن الیافی ارائه میدهیم، همچنین خدمات حرفهای OEM و ODM را فراهم میکنیم تا تجربهای بدون درز و شخصیسازیشده ایجاد شود. ما کل فرآیند سفارشیسازی را نظارت میکنیم و محصولات طراحیشده بهصورت اختصاصی تولید میکنیم که کاملاً با چشمانداز پروژه همسو باشند. با اکو-آرچ، سفارشیسازی فراتر از یک خدمات ساده است؛ این تعهد ما به ارائه کیفیت سفارشی است که ارزش زیباییشناختی و کارکردی تلاشهای ساختوساز شما را افزایش میدهد.

ظرفیت تولید عظیم شانگهای اکو-آرچ بهطور خاص برای پاسخگویی به نیازهای پروژههایی با هر مقیاسی طراحی شده است و تأمین سریع و پایدار مواد را فراهم میکند. تأسیسات تولیدی این شرکت، مقادیر زیادی از مواد ساختمانی مانند سنگهای نرم تراورتن سهبعدی و بتن نیمهشفاف را بدون کاهش کیفیت تولید میکنند. ظرفیت قوی آن بیش از ۱۰۰٬۰۰۰ مورد همکاری را تاکنون پشتیبانی کرده است که امکان پاسخگویی مؤثر به نیازهای بازارهای بینالمللی و داخلی را فراهم میسازد. ظرفیت تولید عظیم و فرآیندهای کارآمد، تأمین پایدار مواد را تضمین میکنند. این امر به کاهش زمانهای تحویل کمک کرده و بتن الیافی شما را در مسیر صحیح نگه میدارد. اگر قصد اجرای یکی از توسعههای کوچک مسکونی ما یا یک پروژه ساختوساز تجاری عظیم را دارید، قابلیت تولید اکو-آرچ اطمینان میدهد که مواد مورد نیاز شما، در زمان مورد نیاز، با بالاترین کیفیت و قابلیت اطمینانی که برند اکو-آرچ را تعریف میکند، در اختیار شما قرار خواهد گرفت.